| HOME | | | Overview | | | The Team | | | About | | | Newsletter | | | Contact | | | Links | | | Friends | | | The Novers | | | Benson Hydro | | |

|

|

Benson's Brook Hydro Scheme | The Titterstone Hydro-scheme

It seems from the dates above that the Titterstone hydro scheme was certainly in the fore of this expanding industry and as such is an extremely significant survival. Its isolation has meant that it has survived largely intact and in an excellent state of preservation. The dam itself is a basalt (dhustone) sett wall which is built across the deep valley of Benson’s Brook between SO58056,77115 on the north side of the valley and SO58069,77072 on the south side giving a total length of 53.5m. The dam wall is a substantial stone wall 0.9m thick standing to a height of 7.2m above the stream bed. Approximately central along the dam is a 3m wide gap in the wall creating an overflow sluice. This would have probably had a wooden sluice gate, the control mechanism for which remains in situ. The fall from the base of the sluice to the stream bed being 6.2m. Towards the bottom of the dam is a rectangular sluice set into the dam face, possibly being designed to allow the drainage of the head pond.

The hydro dam from downstream

Top left image shows the silted and vegetated interior of the reservoir centred at SO5809,7709. Top right the top of the stone built dam wall. Second row left the top overflow sluice gate. Second right the overflow wall. Third row left is a sluice valve within a brick built housing below the dam wall at SO58052,77094 which appears to control the pipe flow from the reservoir.

Bottom left shows the dam wall from downstream to the west, with lower sluice.

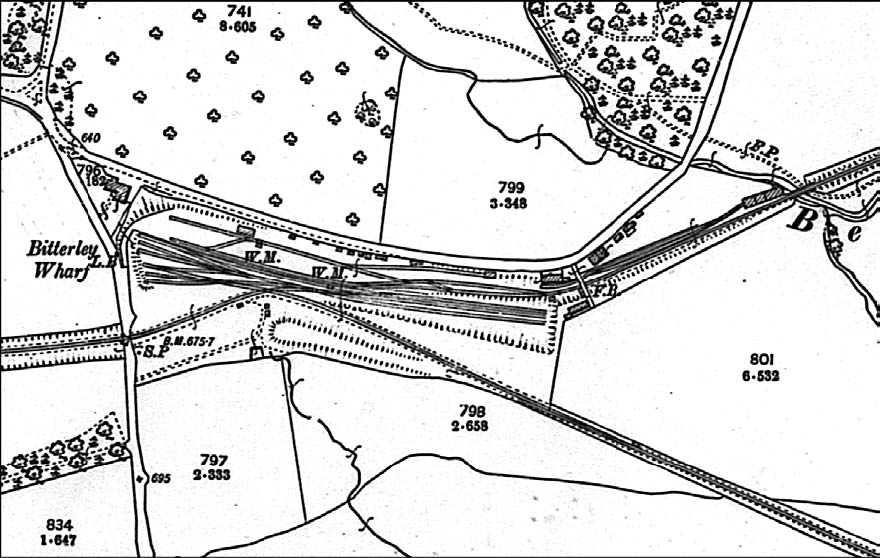

Above the dam the head pond is now completely silted wit Benson’s Brook itself meandering through it vegetated surface. Following the tail back shows the original stone bed of the stream to exist about 65m upstream from the dam. This suggests that the dam may have been built below an existing waterfall step in the stream, maximising the available head. Below the dam the banks of the stream have been revetted with stone walling on either side, preventing any lateral bank erosion. On the north bank of the brook, immediately below the dam at SO5806,7710 is a small brick built valve house. It has sides of 1.7m by 1,4m with walls 0.9m high. Within it is a substantial valve control set into a ten inch diameter cast iron pipe. This seems to be the main conduit from the dam to the turbines which lay down stream, the valve controlling the flow from the reservoir to the turbines. The pipe has been drilled at some time and a modern small bore pipe set into it to allow water to be taken from it. This substantial cast iron pipe runs downstream from the reservoir built into the course of the rail incline which lies here in close proximity to the stream. The 1881 quarry lease makes provision for the construction of a narrow gauge gravity incline plane from the base of the workings at SO59187756 to the rail junction at Bitterly Wharf SO57487690. The construction of the incline seems to have been completed as a primary task to facilitate transport of materials. The integration of the hydro penstock pipe and the incline suggests that the two elements were planned as a whole and implemented at the same time. The course of the penstock can be traced along the incline where it is exposed in concrete bridge sections and appears to have been cast in situ.

Pipe crossing Benson’s Brook

Bitterley sidings

That the remains are those of a hydro power scheme is not in question, neither is the fact that the remains are of high local heritage value and can be considered a regionally significant piece of industrial archaeology.

However what happened once the supply pipe crossed Benson’s Brook is uncertain, it has been suggested that the scheme was designed as a very early hydro scheme but recent information puts this in question. In ‘The Industrial Railway Record No 25 – p94-96 of June 1969 there is the record of a letter from E.H. Jeynes concerning the GWR operated mineral line to Bitterley Yard he quotes a letter from a Mr Farmer which says “ Now in 1913, I was installing electric lighting for Field and Mackay Ltd, and at that time I think there were four crushing plants at work, Nos 2,4,5, and 7, driven variously by steam and suction-gas plants,” [this seems to be a reference to the Titterstone quarry floor crushers]. The text continues to say: “The original No 1 plant had been erected at the Bitterley yard, and had been operated by a water turbine”. TCHT is grateful to Adrian Clayton for bringing this reference to the attention of TCHT.

This clearly suggests that the hydro reservoir and pipeline was built to create a head of water to drive a hydraulic engine. Such technology was well established in this period and the high torque characteristics would have been suitable for driving a stone crusher. Personal information from a gentleman whose father worked in the yard recounted the fact that the hydro engine was not reliable. It is perhaps as a result of this lack of reliability that the crushers were re-located to the quarry with alternative power sources. The fact that Mr Farmer was installing electric lighting in 1913 poses the question, could the hydro scheme have been converted to a drive a hydro electric turbine at this date ?

A more detailed investigation is required to fully record and interpret the water management system associated with this early use of hydro power. No buildings are associated with the works in close proximity to the reservoir, but at SO5755,7691, some 520m downstream from the dam, at a height of 222m AOD the 1903 edition of the OS 1:2500 shows a substantial building immediately west of the brook in close proximity to the hydro pipe. Could this be the No 1 crusher that Farmer describes, the location is now in a private garden and heavily overgrown. It is not possible to fully interpret the remains here or those of the works complex to the south-west without a more detailed investigation. From both the documentary record and the remains on the ground it seems probable that such a detailed investigation would be of considerable value to a more full understanding of this important part of the Titterstone Quarry infrastructure.